Smart Factory Solutions for SMEs

Is Unplanned Downtime Costing You Over 20,000 RMB Per Hour?

When a machine in your factory breaks down, does the entire production line come to a standstill? Without real-time data, every minute of downtime is a huge unexpected loss, and every quality issue is discovered too late. Rising labor costs and inefficient processes are silently eating away at your profits, making it impossible to move your business forward.

Still Managing Your Factory by Guesswork? The Cost is Enormous.

Without real-time production data, you are operating blindfolded. You can only react to problems, not prevent them. Frequent downtime, material waste, and delayed orders, these hidden costs occur daily, preventing you from focusing on strategic planning and ultimately hindering your company’s expansion and competitiveness.

Our services

We propose a three-phase package to progressively transform your factory from its current state into a high-end, intelligent operation. The unique advantage of our system is that the Return on Investment (ROI) from each phase finances the upgrade to the next. This auto-financing rule ensures your journey is cost-effective and low-risk.

Although you will benefit from this pay-as-you-grow model, you will receive the complete vision from the very beginning. This roadmap shows you the full potential of your factory, creating a clear and motivating target to work towards.

Below is an overview of each phase:

Phase 1 : The Digital Pulse

Gain Instant Visibility. Make Smarter Decisions, Faster.

Phase 2 : The Automated Hand

Augment Your Workforce. Boost Consistency & Efficiency.

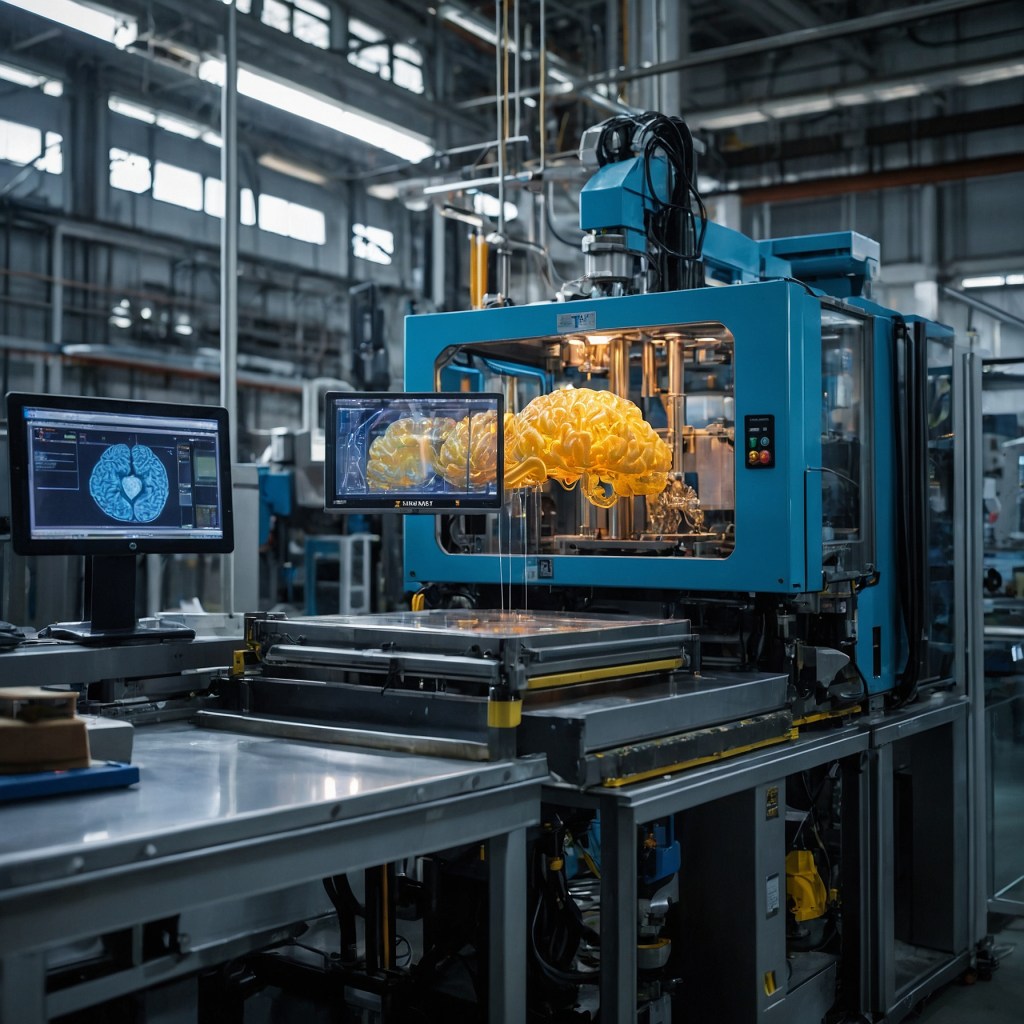

Phase 3 : The Predicting Brain

Transform from Reactive to Proactive. Maximize Uptime & Yield.

About us

At Pinnacle, we are not just technology consultants; we are a bridge between the rich heritage of Chinese manufacturing and its dynamic, automated future.

Our founders bring together two generations of hands-on experience:

- Arthur Cappé, a French engineer specialized in automation and industrial robotics, provides the technical expertise to implement smart factory solutions.

- Yan Wang, who was born and raised in Shantou—the world-famous hub for toy manufacturing—brings an innate understanding of the real-world pressures, challenges, and opportunities on the factory floor. With her father owning and operating a factory in Guangdong for over 30 years, this industry is in her blood.

We saw that for small and medium-sized factories, the path to digitization is often overwhelming. High entry cost, complex installation and low adaptability to current factory’s set up.

That’s why we’ve developed a different approach: modular solutions that work together seamlessly. You can start with a low-cost entry into data visibility, then add on pre-quoted solutions for automated assistance and predictive insights. This allows you to build your smart factory step-by-step, without disruption or excessive cost.

Our mission is simple: to make cutting-edge technology practical, affordable, and effective for the businesses that form the backbone of our manufacturing industry.